Every organization, whether in manufacturing, automotive, aerospace, or healthcare, faces risks. Machines break down, processes fail, and products don’t always perform as expected. These issues can lead to costly recalls, safety concerns, or downtime. To minimize such problems, companies use proven quality and risk management tools.

Two of the most effective are Failure Mode and Effects Analysis (FMEA) and Root Cause Analysis (RCA). Both focus on improving reliability, but they serve different purposes. FMEA is proactive as it looks ahead to anticipate failures before they happen. RCA is reactive as it investigates failures after they have occurred.

Understanding the difference between these two approaches helps businesses know when and how to apply them for maximum benefit.

What is FMEA?

Failure Mode and Effects Analysis (FMEA) is a structured method used to identify potential failures in products, processes, or systems before they occur. Think of it as a way of asking, “What could go wrong, what would happen if it did, and how much risk exposure do we have on these failures?”

Key Features of FMEA

- Proactive tool: Used in the early stages of design or process planning.

- Systematic analysis: Breaks down each step or component to study possible failures.

- Prioritization: Uses three ratings, Severity, Occurrence, and Detection to calculate metrics (e.g., RPN, AP, risk matrices, etc.) to prioritize improvement activities.

- Focus on prevention: Encourages corrective measures that make products and processes safer and more reliable.

Example of FMEA

Imagine engineers designing a car’s braking system. During FMEA, they might consider possible issues like brake fluid leakage. They would then ask:

- How serious is the effect? (High severity because brakes are critical to safety.)

- How effective are the preventive activities that have been applied during design development? (Maybe moderate.)

- How effective are the testing activities at detecting (or exposing) this failure during product development? (Low detectability.)

Based on this evaluation, engineers might add better seals or introduce a sensor to detect pressure changes, reducing the risk before the car ever goes into production.

What is Root Cause Analysis?

Root Cause Analysis (RCA), in contrast, comes into play after a problem has already occurred. Instead of focusing on what might go wrong, RCA focuses on what did go wrong and why. The aim is not just to fix the immediate issue but to apply corrective actions to ensure it doesn’t happen again. These corrective actions should then be applied within the FMEA to capture how effectively the corrective actions are at preventing the failure’s recurrence.

Key Features of RCA

- Reactive tool: Triggered by failures, defects, or safety incidents.

- Investigative approach: Goes deeper than symptoms to uncover the real cause.

- Flexible methods: Common tools include the “5 Whys” technique, Fishbone (Ishikawa) diagrams, and Fault Tree Analysis.

- Long-term solutions: Identifies effective corrective action(s) to eliminate recurrence.

Example of RCA

Suppose a hospital receives a complaint about mislabeled medication. RCA would dig into the problem to see if it was caused by human error, a faulty printer, or a missing inspection step. If the investigation reveals that the printer wasn’t calibrated properly, the hospital might determine that only certified technicians be allowed to calibrate the printer.

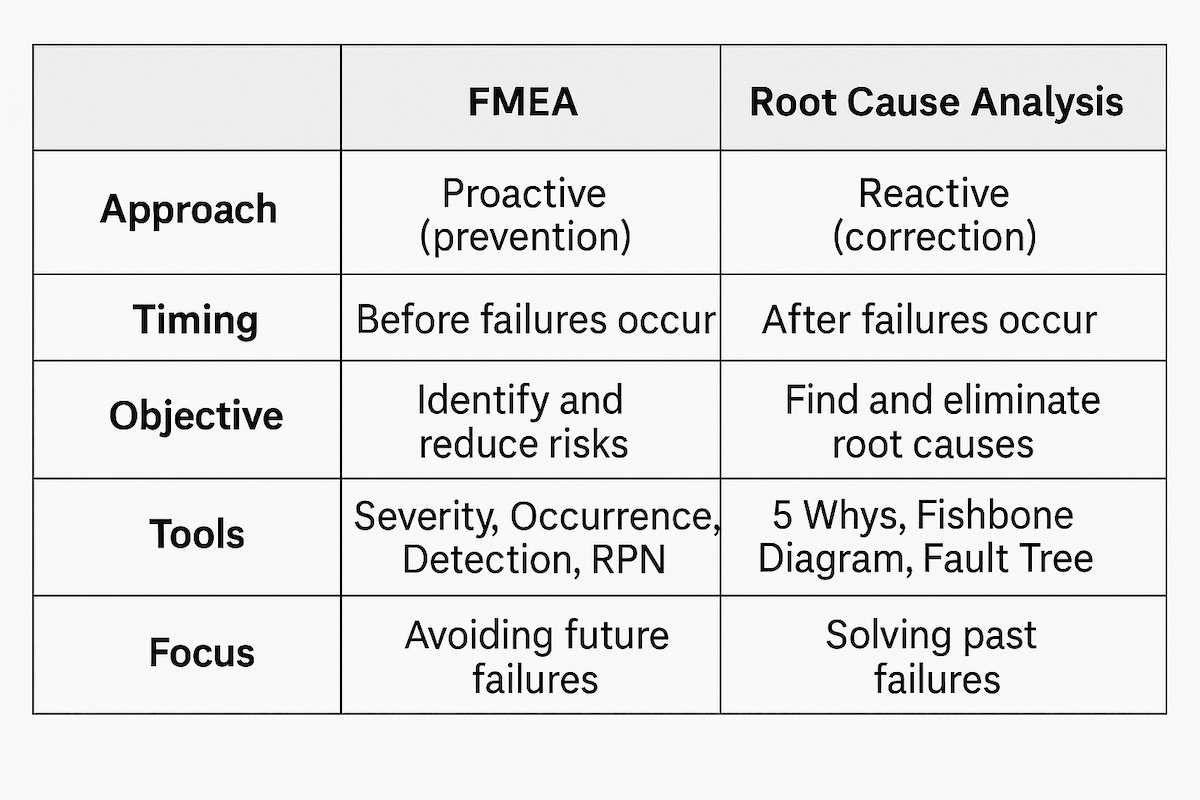

FMEA vs Root Cause Analysis: Core Differences

While both approaches improve quality and reliability, they differ in timing, purpose, and application.

- FMEA is proactive: It prevents issues before they happen.

- RCA is reactive: It fixes issues after they occur.

- FMEA produces a prioritized list of risks and preventive actions.

- RCA produces corrective actions tied to specific failures.

Here’s a simple side-by-side comparison:

How FMEA and RCA Work Together

FMEA and RCA are not competing methods, they work best when combined. FMEA helps prevent problems by analyzing risks early in the process. RCA makes sure that if problems still occur, the true causes are identified and corrected.

For example, a pharmaceutical company may use FMEA on its packaging line to identify risks such as seal failures or misprinted labels. If mislabeled packages still reach customers, RCA would be carried out to find the real cause, such as a calibration error in the printing machine. That insight could then be added to the FMEA so future risk assessments are more robust.

This cycle of prevention (FMEA) and correction (RCA) creates continuous improvement, helping organizations become more reliable and resilient over time.

Benefits of FMEA

- Helps avoid costly recalls and defects

- Improves safety and reliability for customers

- Reduces warranty claims and rework

- Strengthens compliance with standards such as ISO 9001, IATF 16949, and ISO 14971

- Builds customer confidence by demonstrating proactive risk management

Benefits of Root Cause Analysis

- Fixes the true cause of problems rather than just symptoms (when done properly)

- Prevents recurring failures, reducing downtime and waste

- Improves overall efficiency and productivity

- Provides strong evidence for audits and compliance reports

- Promotes a culture of learning and problem-solving within the organization

When to Use FMEA vs RCA

Both methods are useful, but are applied at different stages.

Use FMEA when:

- Designing a new product or process

- Introducing new equipment, suppliers, or technologies

- Preparing for audits or regulatory compliance

- Seeking to reduce risk before production begins

Use RCA when:

- A failure or defect has already occurred

- Customers raise complaints or report safety issues

- A process experiences downtime or repeated failures

- Previous fixes haven’t solved the problem completely

Using the right method at the right time ensures that organizations not only prevent problems but also effectively solve them when they arise.

Real-World Example

The aerospace industry provides a clear example of how these two methods work hand in hand. During the design of an aircraft, engineers perform FMEA to predict potential issues like hydraulic leaks or faulty sensors. These risks are addressed before the plane is built, making it safer from the start.

Later, if a problem occurs during operation—such as inaccurate altitude readings—RCA is used to find out why. If the investigation reveals a software glitch, corrective measures are applied. The findings are then integrated into future FMEAs, improving the safety of future designs.

FAQs

What is the difference between FMEA and RCA in simple terms?

FMEA prevents failures before they happen, while RCA solves failures after they happen.

Can FMEA and RCA be used together?

Yes. They are most effective when combined—FMEA minimizes risks upfront, while RCA eliminates problems that slip through.

Which industries use FMEA and RCA?

Both are widely used in automotive, aerospace, healthcare, pharmaceuticals, manufacturing, and energy anywhere that safety and reliability are critical.

Is FMEA more important than RCA?

Neither is more important. FMEA protects against future risks, while RCA addresses real-world failures. Both are essential for a complete quality management system.

Conclusion

Both Failure Mode and Effects Analysis (FMEA) and Root Cause Analysis (RCA) are essential for building reliable, safe, and efficient systems. FMEA is about prevention—identifying risks before they become failures. RCA is about correction—finding and fixing the causes of problems that have already happened. Together, they create a strong cycle of prevention and correction that leads to continuous improvement.

At APiS North America, we specialize in helping organizations put these methods into action with the APIS® IQ-Software. This powerful tool makes it easier to conduct detailed FMEAs, document RCA findings, and connect both methods in a single system. By working with APiS North America, your organization can stay ahead of potential risks, solve problems more effectively, and meet the highest standards of quality and safety.